Choosing a fall protection connector can be challenging – that’s why we outline several factors that influence this selection in our September blog, Choosing A Connector. The connector blog covers types of connectors, fall restraint versus fall arrest, calculating fall clearance, environmental conditions and types of hazards. The September blog is the place to start for tips on choosing a connector.

Once the decision is made to use a self-retracting device or self-retracting lanyard, often used interchangeably and referred to as either an SRD or SRL, there are still several key factors that influence what type of device is needed.

A Brief Origin

Today’s self-retracting lifelines (SRLs) date back to the individual safety elevator patented by Raymond Fertier in 1961. Fertier’s elevator included a seat connected to a mechanism with a lifeline, drive shaft and disk block. The lifeline wound around the drive shaft and the disk block prevented the counter-rotation of the shaft, stopping the lifeline from paying out during a fall.

Features and Functions

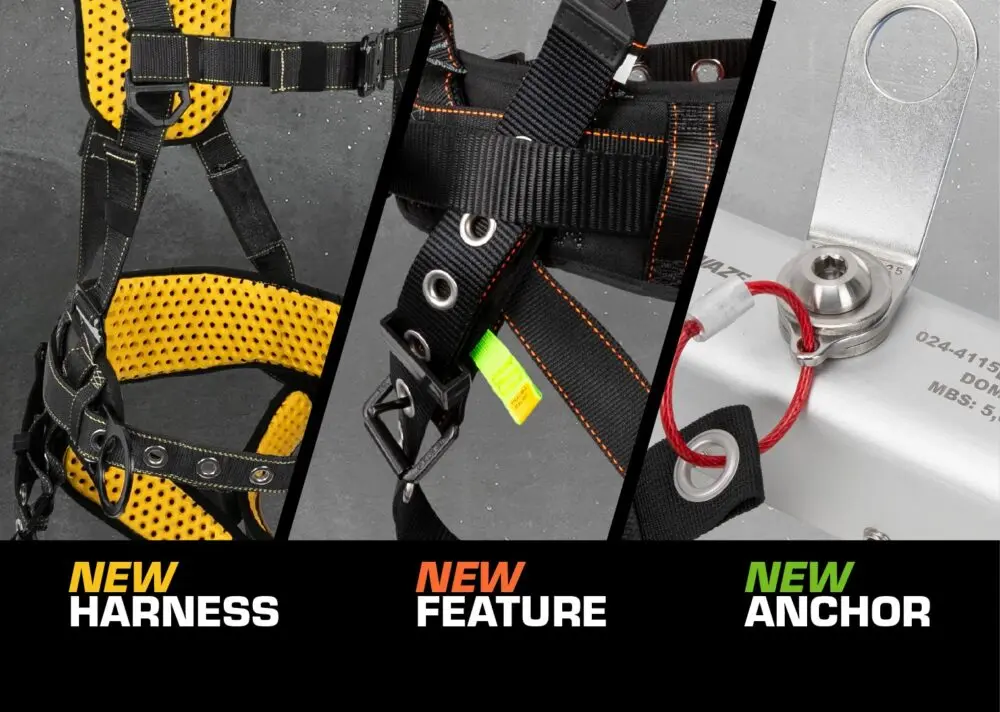

SRLs are commonly used in industries where workers must move around at height, such as construction, manufacturing and telecommunications. These connectors are part of a personal fall arrest system (PFAS) used with a full-body harness and an anchorage point.

- Shock Absorption:The SRL is designed to decelerate a fall within a short distance with a shock absorption system that minimizes the impact on the worker’s body, reducing the risk of injury.

- Retraction:As the worker attached to the SRL moves, the line extends and retracts from the case or housing. A retracting mechanism keeps the line taut, constantly minimizing the distance a worker can fall.

- Tension Control: An SRL maintains constant tension on the line to reduce slack, eliminating trip hazards.

- Durable Materials: Extensive force can be generated during a fall. An SRL must be made of high-strength materials to ensure it can withstand these forces.

- Swiveling Connection: Many SRLs have a swivel mechanism at the connection point, preventing tangles and allowing the worker to move smoothly.

- Dual Leg Options: A single SRL can feature two lifelines, each with its own connection point. These two legs operate independently, allowing workers to disconnect one line while remaining secured by the other.

- Sealed Housing: This specialty feature protects internal components from harsh environmental factors such as salt water, wastewater, oil and other chemicals.

- Tie-Back Functionality: This allows the SRL connector to be “tied back” to the lifeline, eliminating the need for a separate anchor point. These SRLs require hooks and reinforced lifelines especially designed for tie-back.

Different Types of SRLs

A new ANSI standard (Z359.14-2021) went into effect in August 2023 redefining the device types and introducing two new types of lifelines:

- SRD stands for self-retracting device and is the broader category that includes the SRL, SRL-P and SRL-R. SRD and SRL continue to be used interchangeably.

- SRL stands for self-retracting lifeline or lanyard and is still the most common term for a lifeline that extends and retracts. These are widely used for general fall protection across industries.

- SRL-P stands for self-retracting lifeline/lanyard used for personal fall protection. This type of SRL is connected to an individual user rather than to an overhead anchor point and is often lighter with a shorter working length.

- SRL-R stands for self-retracting lifeline/lanyard with integrated rescue capabilities such as a built-in winch to raise or lower a worker after a fall.

Class 1 vs Class 2

ANSI Z359.14-2021 classifies SRLs into Class 1 and Class 2 based primarily on where the SRL is allowed to be anchored in relation to the user and the maximum potential free fall distance.

Class 1 SRLs are designed to anchor at or above a worker’s dorsal D-ring. These SRLs are used for overhead anchorage points with a maximum potential fall distance of 2 feet or less. Class 1 SRLs are not intended for use where the line constituent may come in contact with a sharp or leading edge.

Class 2 SRLs are designed to anchor either above or below a worker’s dorsal D-ring. These SRLs can be used for overhead or foot level anchorage with a maximum potential fall distance of no more than 6 feet over an edge. Class 2 SRLs are engineered for situations where the line constituent may contact an edge during a fall. They are designed to handle the additional stress of such a hazard.

Lifeline Material

The two main types of materials used for the lifeline itself in an SRL are web and cable, with multiple material variations within each of these depending on factors such as the specific use. Plus, the industry is now seeing a third category for emerging materials.

- Web lifelines are made of high-strength synthetic woven material such as nylon or polyester.

- Lightweight – Web SRLs are typically lighter than cable SRLs making them easier to handle and more portable.

- Flexible – The webbing itself is flexible which can make movement easier for the user and is less likely to damage surfaces.

- Non-Kinking – Webbing does not kink or coil like cable which can reduce risk of tangles or difficulty in retraction.

- Non-Conductive – Web materials do not conduct electricity making them safer for work near electrical hazards.

- Less Durable – Sharp and abrasive edges as well as UV light can damage or degrade most webbing materials.

- Specialty – Distinctive materials, such as UHMWPE, Aramid, Kevlar® and other proprietary composites, can be used to reinforce webbing for use in heavy duty or arc flash environments.

- Cable lifelines are made from metal such as steel, most commonly galvanized and stainless steel.

- Longevity – Cable SRLs are corrosion resistant and protected against abrasion, sharp edges, harsh chemicals or environmental conditions.

- Strength – Cable SRLs can often withstand greater forces than web SRLs making them well suited for heavy-duty applications.

- Heavy – The added durability of cable SRLs means they are often heavier than web SRLs and they can cause damage to sensitive surfaces.

- Conductive – Steel cables are conductive, which can be hazardous in environments with electrical risks.

- Inflexible – The rigidity of cable can be more challenging for users who require frequent movement.

- Coated – Cables can be coated with materials such as PVC or nylon to increase durability or weather resistance.

- Emerging materials such as rope and wire rope are relatively new to the SRL market. The terms “wire rope” and “cable” are often used interchangeably though wire rope generally has a larger diameter.

Options for lifeline materials are as varied as the jobs that require an SRL. Both web and cable have a wide range of applications while each has its own specific benefits and limitations. Generally, web SRLs are lighter and more flexible making them ideal for general use, especially where comfort and ease of handling are important. The web material can be less durable in challenging environments. Cable SRLs are known for their durability, often having higher resistance to abrasion and harsh conditions making them ideal for heavy duty and chemical or industrial applications. The cable material can be heavier and less flexible.

Selecting the Right SRL

As you can see, many elements come into consideration when choosing an SRL. Different work environments require different features, types of devices and materials while the location of the anchor point determines which class rating is required for OSHA compliance. If you need further assistance selecting the appropriate SRL for your job site, contact us to speak with a fall protection expert.