- PRODUCTS

-

-

-

Latitude Edge Class 2 SRL-Ps

Combine best in class engineering with Class 2 versatility for use on a wide range of job sites, including the most extreme leading-edge environments.

-

- KNOWLEDGE

- COMPANY

- NEWS

- BLOG

Check Out Our News Topics

June 30, 2025

June 30, 2025

Q2 2025 Spotlight

What Does “Safety Up” Mean for You? As we grow, safety is elevated for everyone!…

June 11, 2025

June 11, 2025

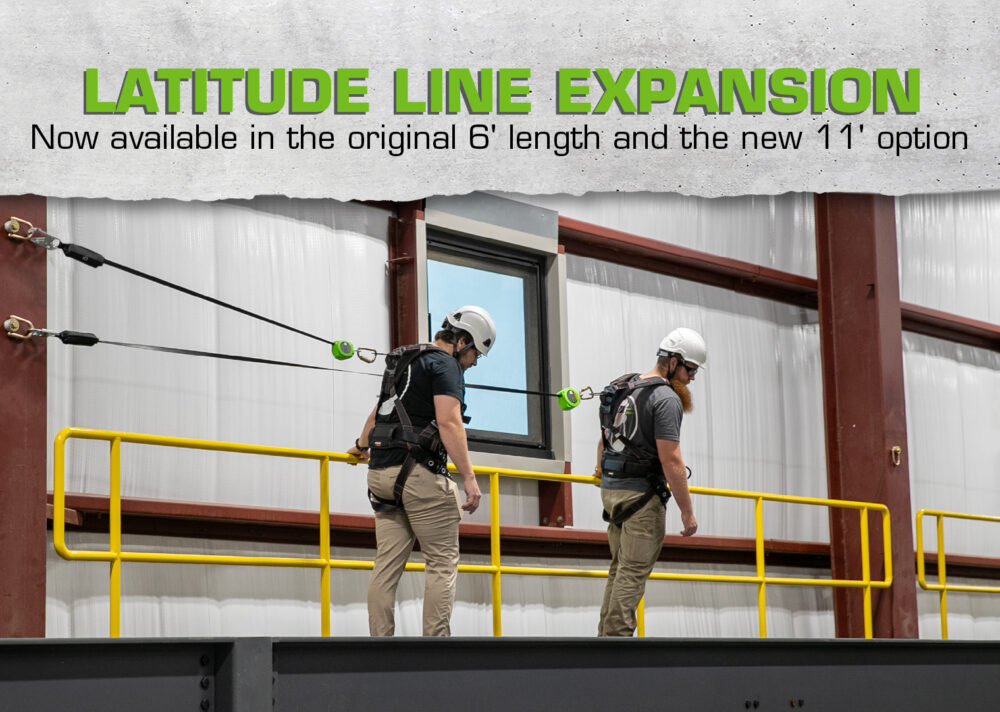

Latitude Line Extension

Get almost TWICE the reach without the bulk with the new addition to the Latitude…

April 8, 2025

April 8, 2025

PRO-Shield Specialty Coated Line

Tough jobs meet their match with the new PRO-Shield Speciality Coated Line! Engineered with a…

March 26, 2025

March 26, 2025

Q1 2025 Spotlight

Reading this spotlight will make you smarter. Guaranteed — learn something or your money back!…