Connector Types and Functions

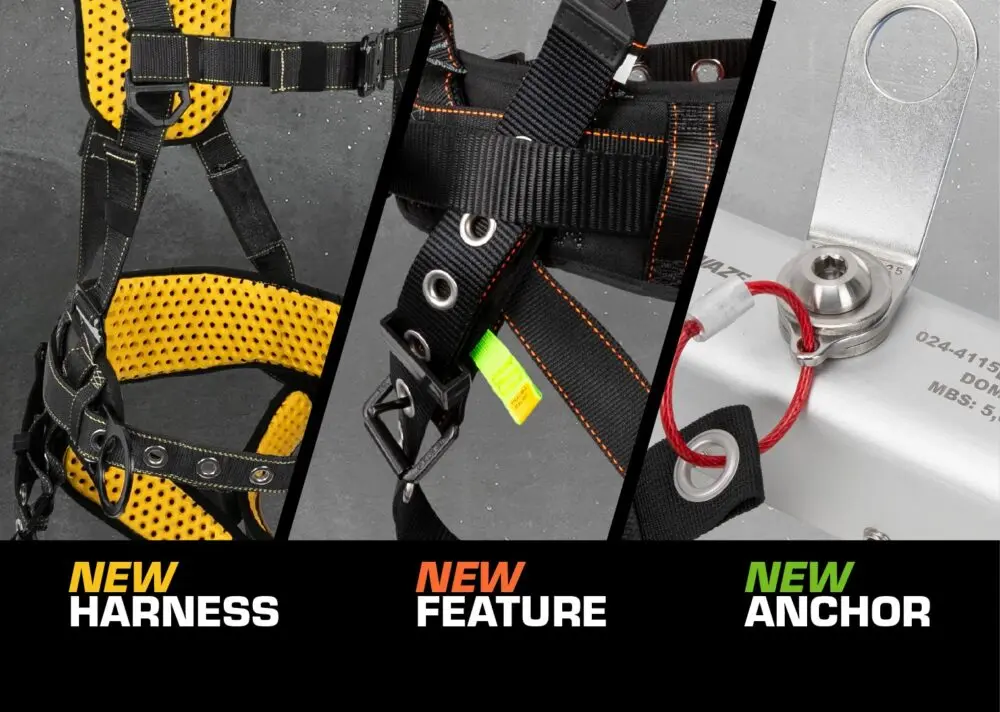

In the context of fall protection, a connector is literally the connection between the worker and the supporting structure. The connection, worker and structure make up the three key components of a personal fall arrest system (PFAS) known as the ABC’s of fall protection – the anchor (supporting structure), bodywear (harness worn by the worker) and the connector (lifeline between the anchor and bodywear). The PFAS is this assembly of components that are used to arrest a person’s fall and manage the forces upon the worker.

The two most common types of connectors are lanyards and self-retracting lifelines (also known as yo-yos or SRLs). There are dozens of connector types that play a critical role in ensuring the safety of workers at height. “Which fall protection connector should I use?” “Do I need an SRL or lanyard?” “What length do I need?” These are common questions and choosing the right connector involves several factors that can quickly make this decision a complicated one.

Fall Restraint vs. Fall Arrest

Before we dive into the types of connectors, it helps to understand the basic functions of a connector within a fall protection system. Fall protection connectors act as either fall restraint or fall arrest. Fall restraint keeps a worker from getting close to a fall hazard in order to avoid a fall. Fall arrest stops a fallen worker from hitting a lower surface after a fall has occurred.

Lanyard

A lanyard is a flexible line of webbing, rope or wire that connects the harness to an anchor point. They are usually a fixed length, generally lightweight and often used when workers need to easily move around a work area.

There are two main types of fall protection lanyards:

- Shock-Absorbing Lanyard: This type has built-in shock absorbers designed to reduce the force of impact on the worker’s body in the event of a fall, minimizing injury.

- Non-Shock-Absorbing Lanyard: These are used for fall restraint and positioning applications. In restraint, no shock absorption is needed because the worker is restrained and therefore prevented from falling. In positioning, falls are limited to a free fall distance of 2 ft. or less.

Self-Retracting Device (SRD)

Self-retracting device (SRD) is the broader category of devices with a housing containing a drum-wound line that retracts and extends as the worker moves, keeping the line taut and minimizing slack to reduce trip hazards. SRDs include self-retracting lanyards (SRLs), self-retracting lanyards with integral rescue capability (SRL-Rs) and personal self-retracting lanyards (SRL-Ps).

Self-Retracting Lifeline (SRL)

A self-retracting lifeline or self-retracting lanyard (SRL) is a general term used for any fall protection device with a braking system that automatically locks at the onset of a fall, arresting the fall and reducing forces on the worker. When using a self-retracting lifeline, they feature an energy management system with either an internal brake system or external shock pack.

Simple Connector Differences

In a personal fall protection system, choosing between a lanyard and an SRL depends on a number of factors, including personal preference, weight, mobility, fall distance, fall clearance, the environment and the associated hazards. All are crucial in protecting workers from injuries related to falls. Below are a few simple generalizations to consider before diving into the more complicated areas of fall clearance, environment and hazards.

- Personal Preference: Even after all other factors are considered, a worker may simply prefer one style over another. Luckily, there are enough options for both SRLs and lanyards to fit every application.

- Weight: Every ounce matters to workers at height, especially with equipment that is carried on their body up and down ladders, across rooftops and over equipment and edges. Overall, lanyards are typically lighter than SRLs though both come in a range of weights.

- Mobility: Lanyards may allow more freedom of movement overall however the yo-yo effect of SRLs reduces trip hazards.

- Material: Both SRLs and lanyards come in cable, web and rope with many more variations in the specific types of materials to best fit the specific needs of the job.

- Fall Distance: Generally, lanyards result in longer fall distances, while SRLs are designed to stop a fall within a shorter distance.

What is Fall Clearance?

Fall clearance is the minimum distance needed for equipment to arrest (or stop) a fall and keep a worker from striking the ground or the next lowest surface. It is not a simple distance calculation. Fall clearance calculations must be carefully performed by an appropriately trained professional as there are many factors to consider, such as:

- Anchor Point Location – the height and setback of the anchor point

- Free Fall Distance – the distance a worker falls before the fall arrest system activates

- Lifeline Length – the fully extended length of the lanyard or SRL

- Arrest Distance – the total distance a worker falls before coming to a complete stop

- Harness Stretch – the extension of the harness, or slight stretch, during the fall

- Height and Weight of Worker

- Swing Fall Hazards – an additional calculation when the anchor point is not directly overhead

Why does fall clearance matter?

Simply put, if the connecting device doesn’t match the fall clearance needs, the worker will hit bottom. When the connector fall arrest distance (how far the worker will fall) is longer than the fall clearance (how far the worker can fall), the system will not stop the worker from hitting the ground (or the next lower surface). Imagine using a lanyard that will arrest the fall in 10 ft. – and the worker is 8 ft. off the ground.

Specific applications will call for longer connectors to allow the worker to perform the function of the job, but the fall clearance must always be calculated to stop the fall before a worker hits the next level. A good rule of thumb, in short, is to always choose the shortest connector possible.

What about low fall clearance?

Low fall clearance refers to a situation where the distance between a worker’s anchor point and the ground or surface below is limited, meaning there may not be enough space for a fall arrest system to stop the fall before the workers hits the next lower surface. Be sure to select an SRL designed for low clearance applications and choose the shortest lanyard length to reduce the potential fall distance – and most importantly, be sure the connector meets the fall clearance demands of the job.

The Right Connector for the Environment

The work environment is a crucial factor when selecting a connector for fall protection. Workers can face extreme temperatures, physical obstructions, space constraints and contamination, just to name a few. Always selecting the appropriate connector for the specific work environment – plus recognizing how the environment may change – ensures that the fall protection system remains effective for workers under the exact conditions of the specific job site. Always consult manufacturer instructions for use in high hazard environments.

Let’s look at seven common work environments that will influence a worker’s connector choice.

- Corrosive Environments

Some job sites include corrosive materials so the connectors must be compatible with these materials. Workers exposed to chemicals, saltwater and other corrosive substances must be equipped with safety equipment made from corrosion-resistant materials. Look for connectors made from the right materials or with special coatings to resist corrosion and extend the life of connectors in these harsh environments.

- Electrical Environments

Another hazard workers at height may encounter is electricity. Connectors made from non-conductive materials like plastic-coated steel or synthetic materials, such as a dielectric hook, must be used to reduce the risk of electric shock. Workers must ensure that connectors in these environments have been tested and rated accordingly.

- Confined Spaces

In confined spaces, where mobility and space are limited, workers must use smaller, lightweight connectors that are easier to maneuver and attach. Auto-locking connectors are highly recommended to reduce the risk of accidental disengagement in tight or awkward positions.

- High-Temperature Environments

For environments with high temperatures such as boiler rooms, foundries and welding sites, workers must use connectors made from heat-resistant materials designed to withstand the specific temperature of the job site. In addition, avoid connectors with synthetic parts that may degrade or melt at high temperatures. Note that extreme temperature differences may affect product performance as noted in manuals and must be accounted for in fall clearance calculations.

- Cold or Icy Environments

Cold environments can make it difficult to maneuver or operate safety components. Ensure connectors are easy to operate while wearing gloves. Larger carabiners or snap hooks with user-friendly locking mechanisms are ideal. Consider ice-resistant mechanisms that withstand jamming in freezing conditions. Note that extreme temperature differences may affect product performance as noted in manuals and must be accounted for in fall clearance calculations.

- Explosive or Flammable Environments

Workers in oil refineries, gas plants and chemical facilities may find themselves in environments with a risk of explosion. To minimize the risk of ignition, select connectors made with spark-resistant materials like bronze or coated metals. Choose connecting devices that are designed to be intrinsically safe for use in these hazardous atmospheres.

- Wet or Humid Environments

Workers should use connectors with water-resistant coatings in wet or humid environments to prevent rust and corrosion on hardware and deterioration of webbing. These SRLs and lanyards must also have non-slip mechanisms to prevent accidental disengagement when wet.

The Right Connector for the Hazard

When selecting a connecting device, workers must also consider additional work-related hazards they may encounter. Not only are falls one of the leading causes of injury and death in the workplace, job sites often pose additional hazards that can make work at height even more unpredictable.

Let’s look at four specific potential hazards and recommended connector safety measures.

- Arc Flash

An arc flash is a sudden and dangerous release of energy caused by an electric arc (a sustained electrical discharge). It can occur when electrical insulation or isolation between conductors is breached, or equipment is operated improperly, producing intense heat, light, sound and pressure waves. Industries using high-voltage equipment, such as in electrical utilities or manufacturing, must take extensive precautions to mitigate the risks associated with arc flashes both on the ground and at height.When selecting a fall protection connector to be used around arc flash hazards, there is only one solution. You must select arc-rated connectors designed to withstand the temperatures and energy levels associated with arc flash events and specifically tested to meet the standards for arc flash protection. Safewaze carries both arc flash lanyards and arc flash SRLs.

- Swing Fall

A swing fall is a fall hazard that occurs when a worker in a harness falls while anchored to a point not directly overhead. Instead of falling straight down, the person swings towards the anchor point like a pendulum. This can result in injury if the person collides with nearby structures or objects. Swing falls are particularly dangerous when the fall distance is significant or where there are obstacles in the swing path.To prevent swing falls, anchor the system directly above the work area or minimize the horizontal distance between the worker and the anchor point. To protect against swing falls, you need to use fall protection connectors designed to mitigate the risks associated with swing falls.Here are some fall protection connector considerations for use around swing fall hazards:

- Self-Retracting Lifelines (SRLs): These devices automatically retract as the user moves, minimizing the amount of slack in the system and reducing the potential for swing falls. SRLs are also equipped with a braking mechanism to arrest falls quickly.

- Shock-Absorbing Lanyards: These lanyards include a built-in shock absorber that helps to quickly decelerate the fall and minimize swing fall forces.

- Restraint or Positioning Lanyards: When used with fall arrest systems, restraint devices eliminate the swing fall hazard by eliminating the fall. Positioning devices minimize swing fall by reducing fall distance to 2’ or less.

- Leading Edge

The “leading edge” is the unprotected side or edge of a surface that advances as work progresses, exposing workers to the risk of falling near the leading edge of an elevated surface, such as the edge of a roof, scaffold or construction platform.A leading edge is particularly dangerous because of potential sharp edge hazards. When a worker falls over an edge, the lifeline may come into contact with the sharp edge of the surface. This contact can cut or damage the line, leading to a failure of the fall protection system.Here are some fall protection connector considerations for use around leading-edge hazards:

- Class 2 Self-Retracting Lifelines (SRLs): Class 2 SRLs are specifically engineered for overhead or foot-level tie-off in leading edge applications. These leading edge SRLs are built to handle the unique demands of these environments, featuring rugged construction with durable housing to protect against abrasion and heavy-duty cable or reinforced webbing to prevent cuts and fraying.

- Leading Edge Lanyards: These lanyards are specifically designed to withstand potential contact with a sharp edge. They may be made of heavy-duty cable or reinforced webbing to prevent cuts and fraying.

- Restraint Lanyards: When used with fall arrest systems, restraint devices eliminate the leading-edge hazard by restraining the worker from reaching the edge. This therefore eliminates any chance of a fall.

- Continuous Connection

When should you use a dual leg lanyard or SRL rather than a single leg connector? Both dual leg SRLs and dual leg lanyards feature two hooks as connection points making it easier for the worker to remain continuously connected as anchor points change. One leg remains connected while the worker moves and repositions the second leg. This continuous connection practice, also called “100% tie-off” or “100% fall protection,” ensures that workers are always connected (or tied-off) to a fall protection system 100% of the time. This is critical when moving between anchor points such as in tower climbing or with some rooftop systems. Not only is continuous connection best practice, it is required by law for compliance to OSHA standards.

Choosing an SRL or Lanyard

In fall protection, choosing a connector starts with understanding the specific needs of the job and assessing the nature of the tasks to be performed. This includes evaluating factors such as which types of connectors are suitable, the weight and material options of the different connectors, the mobility needs of the job and whether fall restraint or fall arrest is preferable. The chosen connector must provide reliable protection while allowing the work to be performed efficiently – and keep in mind that the lanyard or SRL must be inspected before each use as well as annually by a competent person.

Additionally, it is crucial to calculate fall clearance, consider environmental conditions and identify potential additional hazards. It is essential that whatever connector is chosen, SRL or lanyard, there is sufficient fall clearance, meaning the connector will arrest the fall before the worker hits the next lowest level. Exposure to chemicals, corrosive elements, extreme temperatures and even excessive moisture can also affect the performance and integrity of the connector, as can hazards such as swing fall and sharp edges.

Selecting a connector that is suited to all the applicable considerations and conditions will ensure the effectiveness of the fall protection system, ensuring safety for workers at height and allowing for efficiency of the job. Have questions on fall protection connectors or need further help selecting the right SRL or lanyard for your job? Contact us to speak with our technical experts or discuss your fall protection needs with a specialist.