Safewaze emphasizes the importance of identifying and addressing safety hazards before they become a threat. Our team is dedicated to helping companies assess potential risks and ensure safe working conditions. This proactive approach not only protects crews but also fosters a culture of safety in the construction industry. We specialize in manufacturing fall protection equipment that contributes to creating safer work environments.

Hierarchy of Controls

- Elimination

The best strategy for safeguarding employees against fall hazards is elimination, or doing away with the risk completely. To make sure there are no places where a worker could fall, this could mean redesigning a workstation or making modifications to the equipment. Businesses need to determine the hazard’s underlying source. The best place to start when establishing a safe workplace is with elimination.

- Passive Fall Protection

The next best option is passive fall protection when elimination is not practical. This includes putting up physical barriers, like guardrails or safety netting, to keep the worker from danger. These obstacles are always present and offer simple protection without requiring the worker’s active involvement.

- Fall Restraint

The purpose of fall restraint devices is to prevent workers from ever entering dangerous locations. Worker safety is ensured by equipment like lanyards and lifelines, which stop workers from entering potentially dangerous locations. The technique is helpful in circumstances where risks cannot be completely avoided or mitigated.

- Fall Arrest

If a fall does occur, fall arrest systems are in place to stop the fall and minimize injury. These systems include harnesses, lifelines, and anchorage points. They are designed to catch a worker mid-fall and reduce the forces on the body, preventing serious injury.

- Administrative Controls

The final layer of protection involves Administrative Controls, which are the policies, procedures, and training to guide safe practices on the job site. While not as effective as physical controls, these measures are crucial to ensure that all workers are aware of potential hazards and can avoid them.

We have developed reliable fall arrest systems to prevent injury to workers with a safety level that is consistent from anchorage points to harnesses. Moreover, we train and educate teams to use these systems effectively. Therefore, safety is not compromised even during challenging situations.

Duty to Have Fall Protection

Understanding OSHA Mandates

Compliance with OSHA mandates is non-negotiable on job sites. Companies are responsible for keeping their teams compliant with all applicable OSHA regulations. Everyone must follow these rules throughout the operations, and workers are to be protected from falling at heights by use of passive or active fall protection such as:

- Guardrail Systems

- Safety Netting

- Fall Arrest Systems

The correct installation of guardrail systems and safety nets and proper use of fall arrest systems is critical for construction safety. We maintain the highest standards of safety and compliance with our products, which must be used properly to be effective. OSHA mandates include fall protection at the following minimum heights:

- 4-ft in general industry

- 5-ft in shipyards

- 6-ft in construction

- 8-ft in long shoring

- 10-ft for scaffolding

- 15-ft for steel-erection decking

- 30-ft for steel-erection bolting

When workers are working over dangerous equipment, they must have fall protection at all times to prevent any hazard. Further, advanced planning has been shown to increase fall protection use by 71%. The most important goal: lives are saved, and workers are protected from injury. Where cost is an issue, consider that OSHA estimates a 4-6x ROI to every $1 spent on safety.

Job Site Roles

Every member of the team must do their part in maintaining a safe site. There are specific job site roles that have different responsibilities. These roles include qualified person, competent person, and authorized person. These roles must be assigned for every work project.

- Qualified Person – Has extensive knowledge, specialized training, and experience.

- Competent Person – Can identify and eliminate risks of dangerous situations.

- Authorized Person – A reliable person to perform a specific duty.

All team members should conduct inspections, oversee safety protocols, and ensure that every aspect of the site complies with safety standards. It is a collective effort that starts with clear definitions of responsibility.

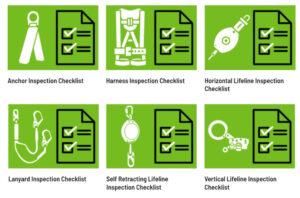

The Importance of Inspections

Inspections are an important safety strategy that allow experts to analyze and identify risks on the job. On job sites, each user must be properly trained in use and inspection. Teams must conduct daily and annual inspections of all safety equipment. The annual inspections must be documented each year by a Competent Person other than the user. Pro Tip: Checklists help.

Using checklists and thorough training, crews ensure that all equipment is in top condition before each use. If any item has not been inspected, it should be removed from the job site. Any item that fails a daily or annual inspection must be immediately removed from service.

The emphasis on regular inspections prevents accidents and develops a culture of safety and accountability on job sites. Safewaze provides the following checklists:

- Anchor inspection checklist

- Harness inspection checklist

- Horizontal lifeline inspection checklist

- Lanyard inspection checklist

- Self-retracting lifeline inspection checklist

- Vertical lifeline inspection checklist

Do not hesitate to remove safety equipment from service the moment it fails an inspection. Experts must follow regulations in these situations. Fall indicators and load-indicating snap hooks are tools to help companies protect their employees. Further, the commitment to protect workers does not end when a fall occurs—it is only the beginning of a rigorous process to prevent future incidents.

Catastrophic Use

After a fall event, it’s crucial to remove any fall protection equipment from service. Each piece must be marked and destroyed to prevent future use. However, certain equipment like retractable lifelines can be repaired and recertified for return to service by Safewaze or an authorized repair center, for safe reuse.

Indicators like extended webbing or red warning bands on snap hooks signal that the equipment has been exposed to a load and must be taken out of service. Properly identifying and addressing these signs ensures continued safety on the job site.

The ABCDs of Fall Protection

Every worker must know the ABCDs on job sites. ABCD includes:

- Anchorage

- Body Wear

- Connectors

- Descent/Rescue

- Education (Bonus)

Proficiency in these components in real-world scenarios is important. The role of workers starts from properly securing harnesses to ensuring safe anchorage points. Each step highlights the critical elements of fall protection.

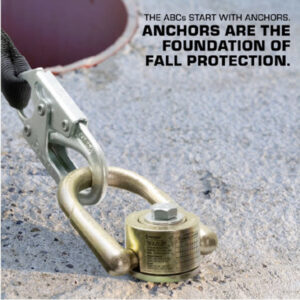

Anchorage

The ABCs start with anchors. Anchors are the foundation of any reliable fall protection system. There are various types of anchors, such as roofing, concrete, steel, strap, and specialty anchors. It is important to secure anchorage to prevent falls and ensure crew safety. The quality of fall protection anchor points can make a considerable difference.

- Anchor Requirements

- The minimum design load of individual anchorage must meet 5,000 lbs.

- Anchors in a personal fall arrest system must maintain a safety factor of two, operating under the supervision of a Qualified Person.

- Anchors used for attaching personal fall arrest equipment shall be independent of those used to support or suspend platforms.

- All hooks attached to the anchor must be fully and securely closed.

Body Wear (Harness)

Body wear helps prevent critical damage during falls. Every team should know the proper use of different types of harnesses. They must understand the importance of a snug fit and correct adjustment to prevent injuries in the event of a fall. Note: 17% of falls are caused by improper use of equipment. Companies must be committed to providing safety for their teams, and we can help them with both education and quality fall protection harnesses. Some types of harnesses include Construction, Full Body, Crossover, Arc Flash, and Specialty.

- Harness Requirements

- A worker in a body harness shall not be exposed to a maximum arresting force over 1,800 lbs.

- The Dorsal (back) D-ring is the only fall arrest connection point – do not attach the connector to side D-rings or lanyard keepers.

- With tongue buckle adjusters, using a center grommet is ideal for the best fit.

- Proper Fit

- Too loose: This can present a choking hazard and may not provide proper protection in the event of a fall.

- Too tight: Uncomfortable and can cause injury such as muscle strains or pinched nerves.

- Sizing and fit: The harness must be properly sized and adjusted for your body.

- Safe fit: Follow the requirements for a correctly sized harness to ensure a safe and comfortable fit.

- Note: Do not alter your harness in any way!

Connectors

Connectors are the vital link between a worker and their anchorage point. We manufacture and sell different types of connectors such as self-retracting lifelines and shock-absorbing lanyards. Workers must know the correct use of each device, a small piece of equipment with a big impact on safety. Training helps keep the workers attached securely and continually protected.

Self-Retracting Lifelines

-

- Self-retracting lifelines (SRLs) are a key component in your fall protection system. Teams can use these devices on various types of projects and selecting the right SRL for each task ensures that the best possible equipment protects crews.

- The cable or web requires 3,600 lbs. of minimum line constituent strength. The maximum free fall limit should be 2 feet. The self-retracting lifelines require auto-locking or double-locking hardware. Never allow lines to “snap” back into housing. The type and functions of the SRL must match the specifications of the job.

Shock-Absorbing Lanyards

-

- Shock-absorbing lanyards minimize the impact of a fall. These lanyards reduce the risks for serious injury. The importance of choosing the right lanyard for the job ensures that crews are equipped with the best possible protection.

- In a 6 feet-free fall, the force allowed on shock-absorbing lanyards is less than 900 lbs. The required deceleration distance is 48” or less. The lanyards offer double-locking or auto-locking hooks. For fall clearance, you must include the 4-foot shock absorber. Multiple lanyards should not be connected. If you tie knots in lanyards, the strength will reduce by 50%.

Positioning Lanyards and Assemblies

-

- Positioning lanyards and assemblies keeps workers securely in place while they work. Education helps workers understand proper use to maintain stability and prevent falls, reflecting a company’s commitment to maintaining a safe and secure working environment.

- According to OSHA, workers should not use work-positioning lanyards for fall arrest as they will not provide workers with shock absorption. Restraint lanyards prevent workers from reaching the fall hazard. Auto-locking or double-locking hardware is required for positioning lanyards.

Descent and Rescue

- In the event of a fall, quick rescue measures can reduce the risk of further damage. Top companies train their workers to be prepared with descent and rescue practice and confined space drills. In addition, we share ways teams can respond swiftly and effectively in an emergency. Planning and practice are key components of safety strategy.

- Training in self-rescue reduces the odds of a fall becoming a fatality by 76%.

- Rescue plans save lives. OSHA requires that a Rescue Plan be included in a project’s Fall Protection Plan.

- OSHA requires a worker to be rescued within 4-6 minutes of a fall.

- Suspension trauma (orthostatic intolerance) begins as soon as a worker experiences a fall and is suspended above the ground.

- While suspended, a worker may become unconscious.

- Fatalities can occur in less than 30 minutes and even as little as 10 minutes.

- Once rescued, a fallen worker should avoid immediately standing until circulation has resumed.

Comprehensive Fall Protection System

A comprehensive fall protection system is a strategic approach to safety. It includes planning, execution, and improvement. It’s important to connect the dots between different components of fall protection as these tools work together to create a system to seamlessly protect workers. Note that the use of fall protection increases 8x when employees believe it’s required by their employer.

Safety is about more than just following rules. It is about a commitment to excellence that permeates every aspect of work. It is a reminder that every step must be guided by a single goal to ensure that everyone goes home safely every day.

Defining a Personal Fall Protection System

A Personal Fall Protection System (PFPS) is a comprehensive safety strategy. Companies integrate anchorage, body wear, and connecting devices into a cohesive system to ensure every worker is protected no matter the task being performed at height.

Meeting system requirements is non-negotiable on job sites. Before beginning any work at height on the job, workers must be trained on the proper use of fall protection equipment and ensure that all proper equipment guidelines are being met:

- All components must be rated at 5,000 lbs.

- The PFPS cannot be designed to allow free fall of more than 6 ft.

- The PFPS cannot be designed to allow more than 1,800 lbs. of force on the worker.

- Workers at height should always attempt to tie off directly overhead.

- Workers should always use the shortest lanyard possible: the shorter the tie-off, the shorter the fall.

- Calculate fall arrest distance to ensure sufficient clearance.

- Consider deadly swing fall (pendulum) in clearance calculations.

Compliance with OSHA standards is not just the law, it is a daily commitment that every company must follow. Fall protection begins with elimination, passive protection and fall arrest systems, and then must also include education and training. Understanding the basics of fall protection is crucial for every worker and companies should continually demonstrate the fundamental components of fall protection with their teams.

Bridging the Gap Between Safety and Work

Ongoing education and training are crucial to maintain a safe daily work environment. Experts must conduct regular training sessions and companies are responsible to train workers with methods from fall protection basics to advanced rescue techniques. Workers need to be able to recognize hazards and be empowered to take the necessary steps to protect themselves and their teammates.

- Continued education and ongoing training is a critical investment to protect the lives and livelihoods of workers at height.

- Nearly 50% of those involved in a fall reported that no fall protection was being used at the time of the fall.

- Workers who are not properly trained on fall protection equipment are much less likely to use it.

- Early training is key ~20% of fatal falls occur in a worker’s first two months on the job.

- Training is the most common change an employer makes after a fall.

Safewaze Can Help

Safewaze prioritizes construction safety through a comprehensive hierarchy of controls that begins with eliminating fall hazards, followed by passive fall protection, and then fall restraint systems. Compliance with OSHA regulations is crucial, with specific requirements for fall protection at various heights. Clear job site roles and regular inspections ensure safety equipment is in top condition. Training on the ABCDs of fall protection—anchorage, body wear, connectors, and descent/rescue—is essential, with ongoing education improving safety practices. Safewaze’s commitment to high standards in equipment, training, and education aims to prevent accidents and protect workers on site.

Learn more on our fall protection FAQs page.